Willard Says……

Dredge Size

When assessing a dredge one of the first questions that comes to mind is, “What size is it?” Some answer with the diameter of the suction pipe or the pump suction inlet diameter. Others will say it is the diameter of the pump discharge port.

Which answer is correct?

A typical dredge might have a pump with a 12” (discharge) x 14” (suction) x 40” (impeller diameter) and therefore could be called either a 12” dredge or a 14” dredge.

Dredges may have pump ports that are the same size, however, it is more common for the suction port to be one pipe size larger that the discharge port. Bigger is usually more impressive so sizing a dredge in reference to its pump inlet port would seem natural.

Pump Curves

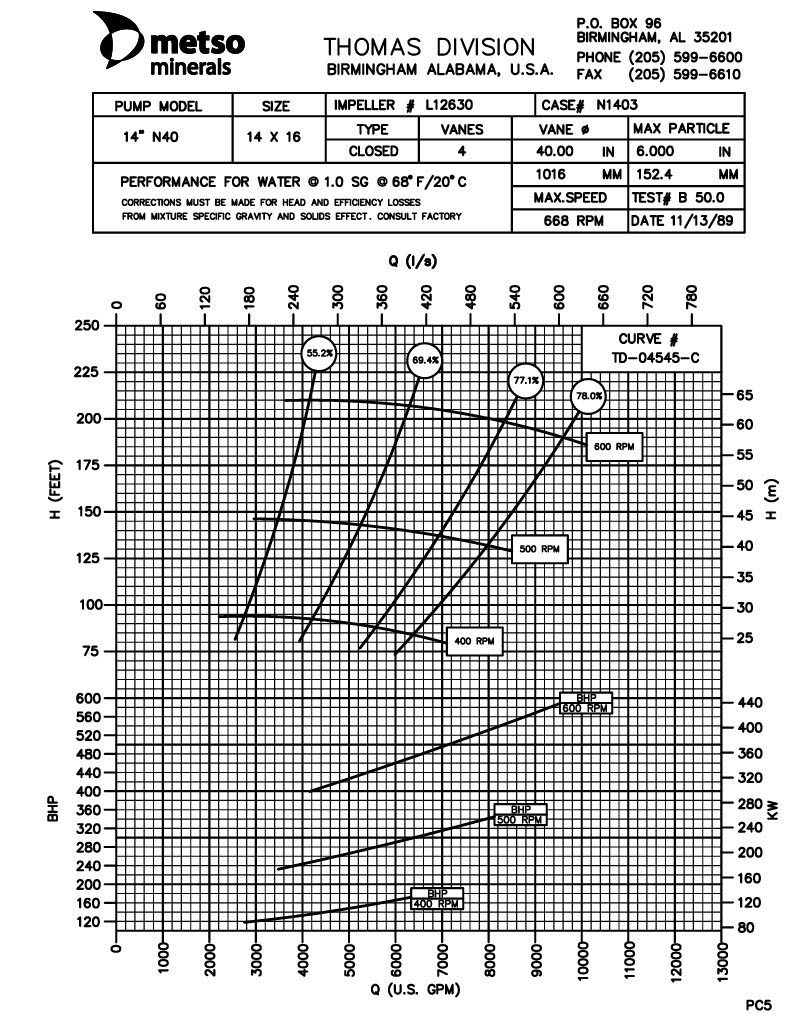

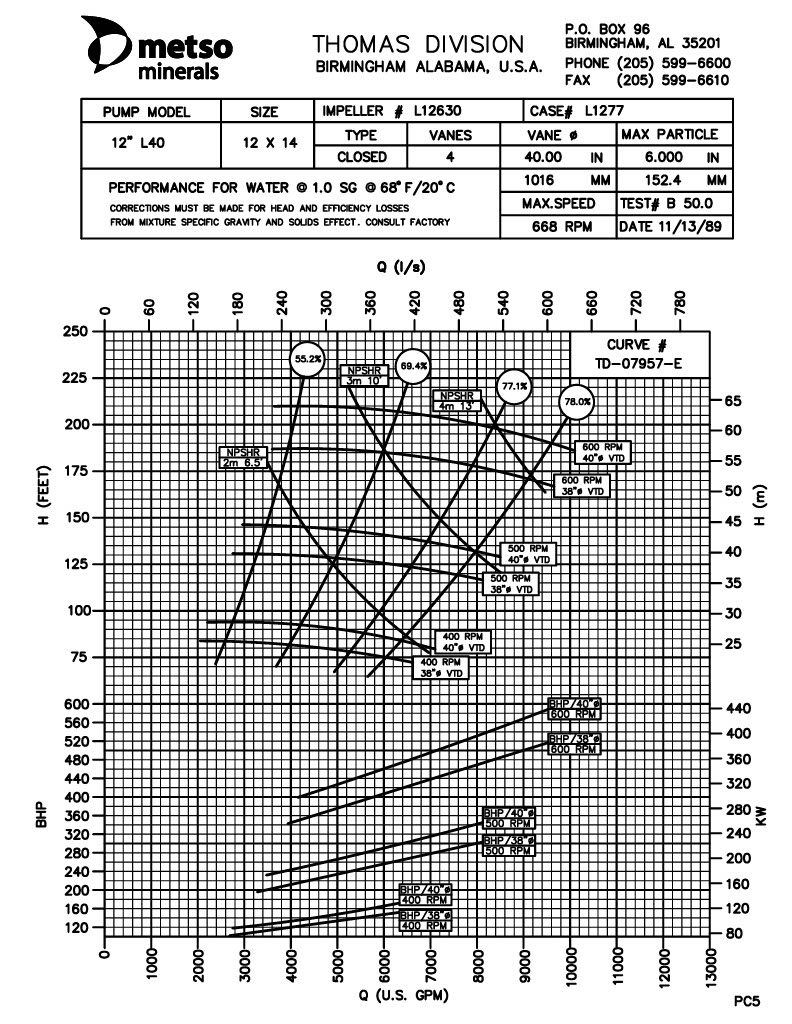

Below are two pump curves. These curves project the performance of two standard Metso dredge pumps, one a 12” x 14” pump and the other a 14” x 16” pump. Both pumps have 40” diameter impellers.

Note that the two sets of curves are identical; they project identical performance for the two pumps despite the difference in their port sizes. (Ignore the lines labeled “38” VTD”, they refer to a 38” diameter impeller). A dredge, outfitted with the larger pump, could be labeled as being a 16” (suction port size) dredge while in fact possessing no more capacity to move solids than a “smaller” dredge labeled as a 12” (discharge port size) dredge. How can that be?

Pump Impeller

The reason the two different sized pumps are projected to have the same performance is because they have the same impeller. Dredge pump impeller diameter is seldom considered when assessing the worth of a dredge even though it is the working heart of a centrifugal pump and has a large effect on dredge performance.

Dredge Pipeline

Also ignored is the fact that most of the energy consumed by a dredge is expended to overcome resistance to flow in the discharge pipe. The inside diameter of the discharge pipe largely determines how much and how far solids can be pumped as well as how much energy must be spent to accomplish the task. The dredge pump must be capable of maintaining flow in the selected pipe.

Referring to the pump curves once more you will note that the numbers across the bottom list flow rates in terms of thousands of gallons per minute. Both pumps are rated to perform best at flows in the “sweet spot” between 5,000 and 7,000 gallons per minute. Operating in this area the pumps can develop high head (pressure) and run with good efficiency. In general both pumps will do a fair job of producing with a 10” pipe, a good job with a 12”, an excellent job with a 14” pipe and a poor job with 16” pipe. All pipe sizes reference the inside diameter.

The problem with using 16” pipe is that neither of these pumps can create enough flow (gpm) to maintain sufficient velocity in such a large pipe.

Horsepower and Speed

These pump curves tell us that maximum performance of either of these pumps will require about 550 horsepower to turn the pump at 600 rpm, develop a head of 200 feet and move water at the rate of 8,000 gallons per minute. Dredge size does not indicate how much power is available to drive the pump or how fast it can be turned although both factors are very important. The curves also indicate that attempts to boost dredge performance by grossly increasing the power available to the pump are wasted. Centrifugal pumps can utilize only a limited amount of power.

Conclusion

It would not be wise to base expectations of performance on a dredge’s “size”.

Any projection as to how a particular dredge will perform depends on the capability of its pump (as described by its pump curve), available horsepower and the inside diameter of the discharge pipe that will be connected to the pump.

The one number that comes closest to describing the performance potential of a dredge is the discharge pipe inside diameter in inches.

Contact willard@willardsays.com with questions, comment or criticism.