Useful stuff to know about hydraulic dredging.

Willard Says……

Slurry density is:

- Poorly understood.

- The ratio of the weights of a volume of slurry relative to an identical volume of clear water expressed as a percentage.

- A measure of dredge system productivity.

- Measured using a nuclear density meter.

- Useful for dredge calculations only if expressed as percent by weight.

- Of little use if expressed as percent by volume.

- Often used to make impossible productivity claims.

- Integrated with velocity to obtain the rate of solids production.

Table 1 lists the values of various densities by weight, by volume and specific gravity. Linear relationships do not exist between these values so they must be calculated.

Table 1

DENSITY

|

Density Solids Percent By Weight |

Density Solids Percent By Volume |

Specific Gravity of Slurry |

|

0 |

0 |

1 |

|

10 |

4 |

1.07 |

|

20 |

9 |

1.14 |

|

30 |

14 |

1.23 |

|

40 |

20 |

1.33 |

|

50 |

27 |

1.45 |

|

60 |

36 |

1.61 |

|

70 |

46 |

1.77 |

|

80 |

60 |

2.0 |

|

84 |

66 |

2.11 |

|

90 |

77 |

2.28 |

|

100 |

100 |

2.67 |

84% by weight = Plugged Pipe

Notes on Table 1

As noted above, percent solids by volume is not used when referring to dredge system performance because that reference does not take into account the density of the solids particles.

The density of the solids—their specific gravity—has a tremendous effect on the performance of a centrifugal pump as well as the manner in which they can be expected to flow through a pipeline. A cubic foot of the solid stone, the stuff of which sand and gravel is made, weighs about 167 lbs. A cubic foot of water weighs 62.4 pounds. The specific gravity (S.G.) of stone is the ratio of the weights of a cubic foot of stone and a cubic foot of water. The S.G. of stone is 167 lbs./c.f. divided by 62.4 lbs./c.f. = 2.67.

In contrast, solid coal weighs about 90 lb. per cubic foot and has a S.G. of about 1.44. Pumping relatively lightweight coal is a vastly different proposition than pumping heavier sand and gravel. For this reason, only percent solids by weight is useful in dredging calculations.

TWENTY percent average density by weight used to be an acceptable rate of dredge production. Even today the unknowing use this piddly rule-of-thumb rate to project dredge production. Only dredgers with extremely low expectations are satisfied with such a pee-poor rate of production.

THIRTY percent average density by weight is a more realistic goal given the availability of information, modern instruments, controls and effective diggers.

FORTY percent average density by weight should be the goal of aggressive dredgers. To maintain this rate of production, however, the dredge must be equipped with very good instrumentation and a suction side stability system such as Twinkle Co’s CONVAC valve. Forty percent requires that the intake of solids into the dredge system be regulated automatically. Continuous production at such a high density is almost always beyond the ability of an operator using manual controls and a vacuum gauge.

FIFTY percent average density by weight is theoretically possible, however, it is impractical to project dredge performance at such a high density because it leaves no room for error. A plugged pipeline is very likely to result if a “slug” of solids enters the suction or chokeoff stops flow into the suction when the system is loaded with such a high-density slurry.

Flows with a density of fifty percent by weight are more likely to be found in industrial pumping situations where density, velocity and particle size can be controlled very precisely.

Contract cutterhead dredgers claim they can pump a density of 50 percent by weight, however, investigation reveals this to be true only about half the time. They achieve a very high density only while swinging in the “digging” direction. The return swing reaps relatively few solids which means that the density delivered through the pipeline averages out in the range of 25 to 30 percent by weight.

Successful sand and gravel and dustpan dredgers strive to mine and pump and produce continuously. There should be no reason to pause or dilute or flush the pipeline. The causes of interruption should be identified and eliminated. Sand and gravel dredgers who use contractor-type-dredging procedures fail in this regard. The idea of constantly swinging the suction inlet through an arc promotes interruptions in production. The correct, efficient, productive path to success is to maintain a continuous, controlled, high-density flow. To average 40 percent solids by weight is a worthy goal.

Where There Be Dragons

FIFTY PLUS percent average density by weight in a pipeline reminds me of the warning on old maps. Unexplored areas on old maps used to carry the warning, “Here there be dragons.” That warning applies to pipeline flows with a density greater than 50 percent by weight. The “dragon” is a plugged pipeline.

A plugged-solid pipe has a density of about 84 percent by weight. Table 1 shows slurry with that density to have a specific gravity of 2.11. The weight of one cubic foot of this slurry is 2.11 times heavier (132 lbs.) than one cubic foot of clear water (62.4 lbs.)

Reference books show the weight a cubic ft of dry packed sand and gravel to be about 110 lbs. Table 1 shows that a slurry with a density of 84 percent by weight has a solids density of 66 percent by volume which means that the voids between the particles makes up the other 34 percent of the cubic foot of slurry. It requires 21 lbs. of water that fills those voids. (62.4 lbs. per cubic foot of water multiplied by 34 percent of a cubic foot.)

This exercise shows that a cubic foot of slurry in a plugged pipe consists of 21 lbs. of water and 110 lbs. of solids for a total weight of 132 lbs. and has a density of 84 percent by weight with a specific gravity of 2.11.

The next time some cowboy spouts off about how he or his machine can pump a slurry with a density over 50 percent by weight you now know that he; 1. Has been smoking his socks. 2. Is talking about a concrete pump. 3. Is full of slurry.

Measuring Density

The most accepted method of measuring dredge flow density is to use a nuclear density meter. This two-component device straps to the outside of the dredge discharge pipe. One component, the emitter, houses a weak radioactive element in a well-shielded container. After mounting on the pipe, the emitter shutter is opened so that a narrow beam of radioactive particles can “shine” through the pipe. The other component, the detector, is clamped to the pipe at a position 180 degrees opposite the emitter. The detector registers the strength of the radioactive beam after it has passed through the pipe. The beam strength when the pipe is full of clear water is noted and calibrated as “zero” density. The strength of the beam is degraded or lessened in proportion to the density of the solids flowing through the pipe. When properly calibrated, the density meter will indicate the density of the slurry flowing inside the pipe.

Automation Using Density Does Not Work

Several attempts have been made to utilize the density reading as a guide to automate dredge operation. All have failed and for valid reasons:

- The indicator does not reflect a continuous sampling of the density, rather it is the average of a continuous series of instantaneous snapshots spaced a second or so apart.

- The snapshot densities vary widely. If these readings were shown on the display the result would be a meaningless procession of impossible-to-read numbers.

- An accurate average indication of density is achieved by damping. That is accomplished by electronically calculating and displaying a running average of the all the snapshot readings taken over a short period of time, perhaps 10 seconds. This electronic process called damping provides an accurate, usable indication of the average density that has recently passed through the beam. Damping delays the indication of any change in density that may be significant in adjusting the rate of solids intake at the suction inlet.

- The density meter is usually installed on the dredge discharge pipe at a point significantly distant from the suction inlet which means that the indicated density reading reflects the intake of solids that occurred several seconds before.

- Effective dredge system operation and control depends on the precise regulation of the rate at which solids enter the suction pipe. An immediate response of appropriate magnitude is required to correct any deviation from the desired rate of intake.

- Using the density reading to control the feed rate of solids into the suction pipe fails because the density reading reflects history. Density snapshots of the flow segment cannot be taken for the several seconds that it takes for the segment to move from the suction inlet to the density meter location and damping further delays the actual readout.

- The delayed density reading cannot provide the real-time guidance required to accomplish rigorous control of the rate of solids intake at the suction inlet.

Measuring Production

Three pieces of information are needed to measure and record dredge production:

- The pipeline inside diameter.

- The velocity of the slurry.

- The density of the slurry.

Measuring velocity for purposes of achieving and maintaining maximum dredge production can be done relatively inexpensively with a Doppler type meter. This instrument projects sound at a certain frequency through the wall of the dredge pipe. The frequency of the reflected sound changes with the velocity of the solids particles and the electronics interpret and indicate those frequency changes as changes in velocity. The accuracy of Doppler-type velocity meters may err as much as 10 percent while pumping solids and even more while pumping clear water.

Accurate measurement of pipeline velocity requires the use of a magnetic velocity meter. These units surround the flow—clear water or slurry—with an electrical field, which varies with the velocity of the flow. Electronic interpretation of the field changes makes possible an accurate display of rate of liquid flow through the device. Accurate production records depend on the use of a magnetic velocity meter.

An electronic integrator combines pipe size, velocity and density to calculate production and display the rate of production in terms of tons per hour or cubic yards of solids. The results are stored along with a tally of the total production over some period of time. The data can be downloaded.

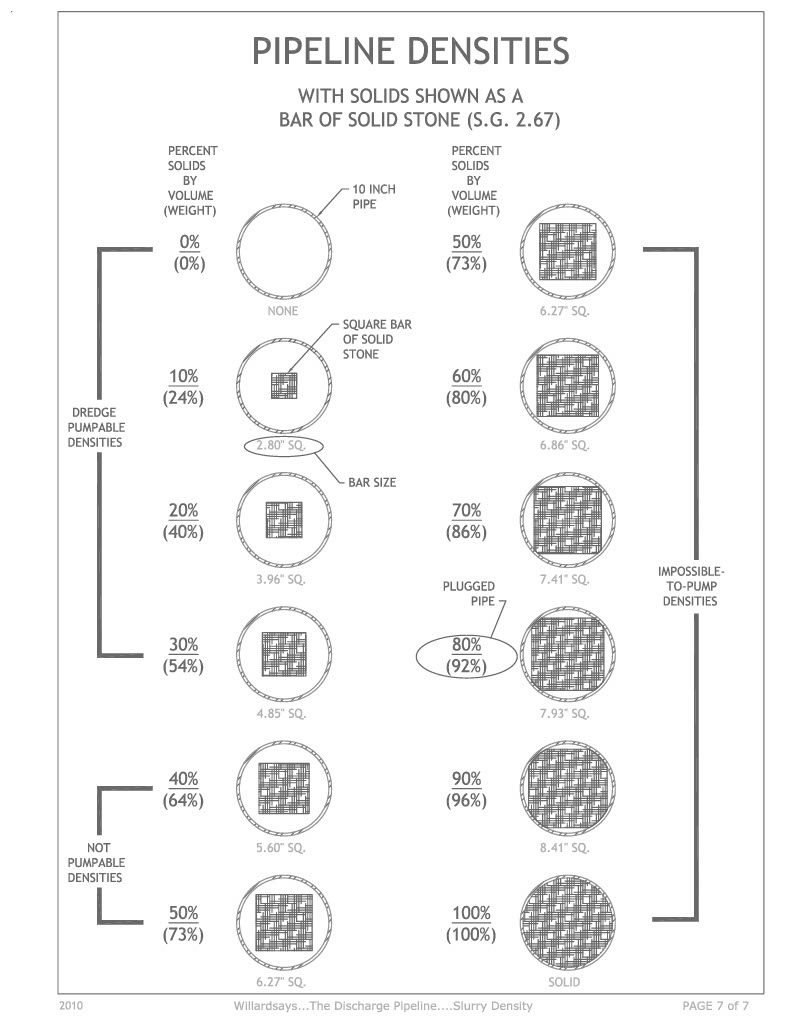

Pipeline Density Seen Another Way

The sketches below provide a means of visualizing the relative quantities of solid stone and water flowing in a 10-inch pipe at varying densities.

Contact willard@willardsays.com with questions, comment or criticism.