Willard Says……

Wire rope is the sinew that enables winch muscle to be applied where it is needed. Wire rope positions the dredge, crowds the cutter into the solids bank and supports the ladder.

Table 9 below provides information on the strength of various sizes of one popular style of wire rope, 6 x 19 IWRC. The rope is made up of 6 strands, each of which is made up of from 16 to 26 individual wires. The six strands are formed about the IWRC (Independent Wire Rope Core). There are many other styles of wire rope, some of which are suitable for dredge use. For instance, galvanized wire rope is appropriate where severe corrosion shortens the life of standard plain-finish cable. Galvanized wire rope has about 10 percent less load capacity than plain-finish cable.

Wire rope size is determined by measuring its widest diameter.

TABLE 9

| ROPE SIZE, INCHES 6 x 19 IWRC | BREAKING STRENGTH IN LBS. | WORKING LOAD WITH 5 TO 1 SAFETY FACTOR |

| 3/8 | 13,120 | 2,600 |

| 7/16 | 17,780 | 3,600 |

| 1/2 | 23,000 | 4,600 |

| 9/16 | 29,000 | 5,800 |

| 5/8 | 35,800 | 7,160 |

| 3/4 | 51,200 | 10,200 |

| 7/8 | 69,200 | 13,840 |

| 1 | 89,800 | 17,960 |

Wire rope has LAY and RELATIONSHIP and LENGTH.

A. LAY is the direction in which the strands “lay” as you look along a length of wire rope. Strands that veer to the right are RIGHT Lay. Strands that veer to the left are LEFT Lay. It makes no difference which way you look down the rope.

B. RELATIONSHIP has to do with the direction the strand wires lay in relation to the direction in which the strands lay. If the strand wires spiral in the direction opposite the direction the strands spiral the rope is REGULAR Lay. If the strand wires spiral in the same direction as the strands spiral the rope is LANG Lay.

C. LENGTH is the distance along the rope that it takes one strand to make a complete spiral around the rope core.

You can now ask, “What the hell does Lay, Relationship or Length have to do with the price of tea in China?” Well: a.) not much and b.) a little extra knowledge will not hurt you.

Seriously, the real significance of these features has to do with the way in which cable winds onto a winch drum. Cable makers say that there is a correct way and an incorrect way. See Willard Says……Winches and learn right from ‘rong.

Sheaves

The sheave grooves should be sized to match the wire rope diameter. If the groove is too small, the wire rope will be pinched and if it is too big the rope will flatten out as it travels over the sheave. Either condition shortens the life of wire rope.

Large diameter sheaves contribute to longer wire rope life by reducing wire flexing. Likewise, large diameter winch drums reduce flexing and extend cable life.

Periodic lubrication extends wire rope life by reducing wear and shielding against corrosion.

Sheave grooves wear with use. Get a gauge from your wire rope supplier and check your sheaves if they have some age on them. Worn sheaves shorten cable life.

We have cheapo plastic gauges (measures wire rope diameter and sheave grooves) in stock. We will send you one free! Ask and you shall receive.

Parts of Line

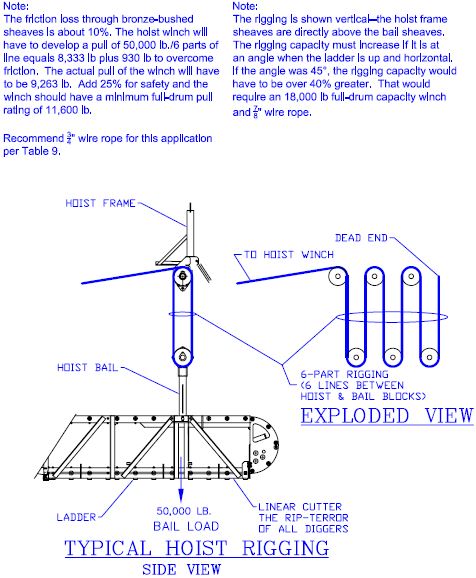

The sketch below shows a typical dredge ladder rigging with a bail load of 50,000 lb. and how to determine the number of parts of line. The parts of line can be determined by counting the number of cable segments that run between the hoist block to the bail block. The parts of line determines the extent of the multiplying effect that makes it possible for a single line coming off the winch drum with a relatively small line pull to lift a heavy load. A friction factor must be applied along with the line part multiplier to calculate the actual lift capability.

Working Load

Table 9 shows Breaking Strength and Working Load with a 5 to 1 Safety Factor for various sizes of wire rope. This is a conservative safety factor recommended for applications where loads will be suspended over people or valuable things. The safety factor for a dredge ladder could be 4 to 1, however, that leaves little margin of safety for a stuck ladder or wire rope wear.

Note that a winch’s line pull capability increases as the effective diameter of the drum decreases.

Using the sketch above, consider what could happen if the ladder became stuck underwater. The effective winch drum diameter may be reduced to only about 60% of its full-drum diameter because cable has been pulled off the drum to lower the ladder. Were this the situation, the line pull would increase from the rated 11,600 lb. shown to an actual 19,300 lb. This changes the safety factor for ¾” cable from a working 5 to 1 to an actual 2.7 to 1. If the winch has a full-drum line pull capability greater than 11,600 lb. rating., the line pull could be much higher and put the ¾” cable further in danger of parting. Do not skimp on rigging!

Wire rope should be inspected on a weekly basis. Replace the cable when broken wires are found.

Comment, question, criticism, information on products mentioned? Contact willard@willardsays.com.