Willard Says……

Several years ago I had occasion to spend some time at a sand and gravel dredging operation that set all kinds of records in my book for avoidable down time—especially to reconnect pipeline joints.

I asked the operating people why they did not make the pipe connections in a way that would prevent parting. Their reply was that management would not pay for the necessary hardware to make “permanent” joints, that they had always had this problem and management certainly would not give the operating people any credit for solving this problem.

Did I mention that this operation also held the record for being one of the worst managed that I had ever seen? To say that management looked upon their employees with disdain would be an understatement. They made no secret that they regarded employees as a necessary evil and abused them at every opportunity.

This situation constituted one of the best arguments for union representation of employees that one could imagine. And they had a union, which provided management with a convenient whipping boy to blame for their lack of efficiency. Labor-management relations were adversarial to say the least.

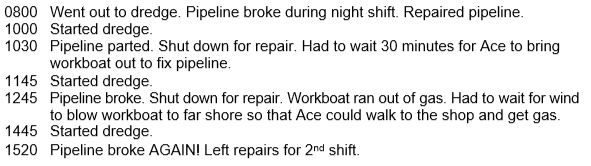

This company must be given credit for insisting that the operators keep a log of dredge operation. Competent management will find a dredge log to be a useful tool. A sample of the dredge log from this dredge is shown below.

Reading these logs made me weary. How could management not take action

to stop this unnecessary

downtime? Well first they had to read the logs

and they did not take the time to do that. In the hands of incompetent management such as this, keeping

a log is a waste of time.

Expert Advice

Back to the pipeline. Management, frustrated by the lack of dredge production and unable to see the forest for the trees, paid a consultant to visit and give them ideas to improve dredge mining efficiency. His major recommendation was to eliminate downtime spent reconnecting the pipeline. He gave them detailed instructions on how to make sturdy pipeline connections.

The consultant discovered, as had I, that the employees were also doing their part to keep the pipeline from breaking. The operators noticed two related phenomena: 1. Discharge pressure increased when production increased. 2. Pipeline partings were more frequent when the pressure increased. Aha! The key to keeping the pipeline together was to keep production down. The operators were not totally successful in preventing pipe parting but they were very successful in preventing full production.

Double Whammy

Production was taking a hit from two directions.

- Intermittent downtime to fix parted joints.

- Full-time reduced production.

Where the hell is management?

You may ask, “Couldn’t management see what was going on?” Yes and no.

Yes, they could look out and see that the dredge was down, that the pipeline was parted and the stockpiles were not growing. They were frustrated but turned a blind eye while maintaining that pipeline parting was just a normal problem of pipeline dredge operation.

No, they did not know that the dredge operator and maintenance people were conspiring to keep production down to avoid pipeline parting. This management group did not visit the dredge or any work areas so as to avoid being mistaken for employees. Only workers should get close to work. Perhaps they were concerned about getting their ties wrapped up in rotating machinery. I think they stayed away to avoid any employee questions to which they did not know the answer and that would have been most any question about dredge operation.

And of course

the union set all the work rules and

job descriptions so management thought themselves powerless.

And so they did little.

The Wages of Corporate Mismanagement–Death

In the hands of those willing to learn and do, a dredge can be a very efficient and profitable tool. In the hands of the ignorant and the incompetent, a dredge can be a source of endless frustration and expense.

Our information is that this company has continued their mismanaging ways accepting frequent pipeline breaks and poor production as normal.

The moral of the story –

Successful and profitable dredge operations do not suffer parted pipelines.

Comment, question, criticism, information on products mentioned? Contact willard@willardsays.com.