Gripping information about practical hydraulic dredging.

Willard Says…

Stringing the hoist cable can be one of the more challenging chores around a dredge. Restringing the hoist cable after it has broken and dropped the ladder deep in the water is VERY challenging. I have come across a little device that can make the restringing chore a lot easier. See Figure #1.

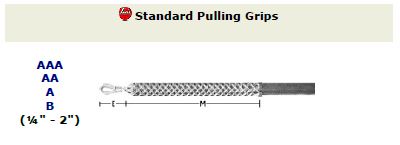

The Snake Grip is a heavy duty version of a kid’s Chinese Finger Trap toy which is a tube formed of fiber strands braided in such a way that it slips easily over a finger yet grips it when an attempt is made to pull the tube off the finger. The harder the pull the tighter the Finger Trap grips the finger, but when the pull force is relaxed the Trap can be easily removed.

Snake Grips (Lewis Grips or Pulling Grips) are available in a range of sizes that will fit any wire rope from www.lewismanufacturingco.com. This slim, flexible device slips freely over the plain end of a length of wire rope and when pulled, firmly grips the cable so that it can be pulled through a series of rigging sheaves without hanging up.

STRING A NEW CABLE

Give thought to how a Snake Grip could make hoist cable stringing much easier.

- Thread 1/4” cable from the dead end point of the rigging through the hoist frame and bail block and connect it to the hoist winch drum.

- Connect the other end of the 1/4” cable to the new hoist rigging cable using the appropriate Snake Grip. Use a short length of intermediate sized cable and two Snake Grips if the jump in size exceeds the jump- size capacity of a single Snake Grip.

- Position the reel of new hoist cable so the 1/4” cable can pull it off the reel and through the rigging blocks.

- Commence reeling the 1/4” cable onto the hoist winch drum.

- Pull two or three wraps of new hoist cable around the winch drum.

- Tie off the hoist cable.

- Disconnect the Snake Grip.

- Remove, coil up and save the 1/4” cable for future use.

- Connect the new hoist cable to the hoist winch and reel the remaining cable onto the winch drum until the dead-end connection can be made on the hoist frame or bail.

- The new cable is ready for service.

Reeving light, pliable 1/4” cable through the rigging blocks will be child’s play compared to having to wrestle a greasy, heavy, stiff hoist cable. A diver will appreciate the difference if the bail block is underwater.

INSPECT HOIST CABLES

All cables suffer constant degradation due to flexing, abrasion, loading and corrosion. Ladder hoist cables are very critical and therefore should be inspected frequently. Hoist cables should be replaced as soon as any broken wires are observed.

Lubricating a cable with a grease does not lessen the load it has to carry, but it will slow the rate of wear due to flexing, abrasion and corrosion. Grease, messy as it may be, does extend cable life.

Inspect sheave grooves. Too-narrow or worn grooves cause wire rope to deform under load. Deformation accelerates internal friction wear, weakens the rope and shortens its life.

REPLACING A HOIST CABLE

A Snake Grip eases the job of hoist cable replacement.

- Support the ladder on its safety chains or slings.

- Disconnect the dead end pull all the hoist cable off the hoist winch drum.

- Cut the old cable off and use a Snake Grip to attach it to the new hoist cable.

- Wind the old hoist cable onto the winch drum and pull the new cable through the rigging blocks.

- Wind two or three wraps of new cable onto the winch drum and tie it off.

- Disconnect the Snake Grip and strip the old cable off the winch drum.

- Connect the new cable to the winch and take it in until the dead-end connection can be made.

- The new cable is ready for service.

Contact willard@willardsays.com with questions, comment or criticism.