Willard Says……

Everyday Wisdom on the Workings of a Hydraulic Dredge

What is Wrong in this Picture?

Figure #1

Six problems loom large in this picture of a rotary cutter dredge ladder.

ONE

Safety! Safety! The operator is not wearing a life jacket. Normally, no one is around to fish him out should he fall into the water. He is on his own.

A worst case scenario came to pass in another sand pit not far from the one shown above. The owner came in early one morning and noted that the night operator’s car was still parked near the landing area yet he was nowhere to be seen. The owner had to go borrow a boat to go out to his dredge. (MSHA says there must be two boats on site.) He found the lifeless, life-jacketless operator gently bobbing face down in the water a short distance from the dredge. The now ex-operator was known to do exactly what the guy pictured above is doing—attending to a cutter problem while teetering around on the ladder without a life jacket. It appeared that he had fallen and hit his head on his way into the water.

The company soon went out of business due in no small part to the heavy fines and hefty increase in insurance premiums brought on by this preventable fatal accident.

TWO

Design deficiency! The ladder frame is not only straight, it bends upward at the cutter end. This arrangement causes heeling off which occurs when the bottom of the ladder just aft of the cutter basket comes to rest on a bank of solids. The ladder in the picture obviously heels off as proven by the absence of paint and the presence of sandy material clinging to the bottom side of the ladder just to the rear of the cutter basket. Production tapers off when heeling occurs because the cutter cannot be let down any further to cut more material loose. The operator, after fruitless attempts to lower the ladder, tries to swing sideways and finds that the ladder cannot be swung because it is digging into the bank upon which it is resting. His only solution is to pick up the ladder and look for another spot where the cutter can be brought into contact with material. Naturally production has gone south while all this maneuvering is going on. Usually, if heeling off happens once it will happen again. And again. See Willardsays….The Dutchman for solutions to heeling off.

THREE

More Design Deficiency! The arrangement of the cable rigging that supports the end of the ladder imposes unnecessary strain on all parts of the hoist system. Eventually, one abused component will be overloaded where upon it will fail and the ladder will fall.

The problem arises due to the angle of the three-part cable rigging as it extends from the hoist frame block near the top of the picture to the hoist bail block on the ladder. That angle, about forty five degrees off of vertical when the cutter basket is just clear of the water, creates far higher loads than would be the case if the angle were five degrees or less. The load on the system shown in the photo will increase dramatically if an effort is made to raise the ladder higher than shown. The rigging angle could easily be reduced to near zero by attaching the bail block further back on the ladder.

FOUR

The open-bladed cutter basket has no sifting ability. Note the large opening between the blades. An oversized rock can pass between the blades, enter the dredge system and cause downtime when it lodges in the pump.

Dredging Commandment VI says, “ Thou shalt cause an excess quantity of pumpable solids to be continuously available at thine suction inlet.”

Pumpable solids do not contain unpumpable rocks!

See Willardsays….Rotary Cutters—Bladed Baskets.

FIVE

More Safety, Safety, Safety! The ladder support safety cable is not connected to the ladder. The lone, wimpy cable hanging vertically from the top of the hoist frame is obviously meant to support the ladder when the rigging system is out of service. While it is not clear in the picture above, there is a shackle hanging in the loop at the bottom of the cable and it is not connected to anything.

When this picture was taken, some twenty years ago, ladder safety cables were seldom connected unless the rigging system was going to taken out of service. Today, MSHA inspectors consider it a violation if safety supports are not connected whenever personnel present on the ladder for any reason.

SIX

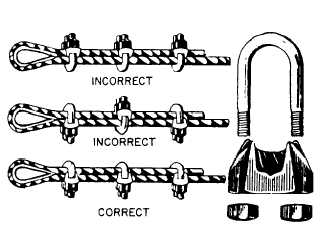

Sometimes its the little things that cause really big problems! Note the two clamps on the ladder safety support cable. Only the top one is installed correctly. Note the three clamps that dead end the hoist cable. Only the upper two are installed correctly.

What makes the correct way correct? See Figure #2. Cable clamps should always be installed with the saddle half bearing on the loaded section of the cable. The saddle half grips without distorting the cable’s strands while the U-bolt half of the clamp always crimps some of the strands and reduces its rated strength.

Double-saddle cable clamps are available but seldom seen. See Figure #3. These clamps feature two saddles so they cannot be installed incorrectly.

Contact willard@willardsays.com with questions, comment or criticism.