Willard Says……

Hullpump vs. Ladderpump is the choice that must be made by those who are in the process of buying a dredge, I will shovel a few facts into the hopper of this discussion to enlighten the reader.

The first fact to keep in mind is that there is NO difference between the wetted parts of the two pumps. Hullpump shell, liners and impeller will interchange with the ladderpump parts of the same brand.

The difference between the two styles of pump is strictly mechanical. The ladderpump drive shaft must be sealed to prevent water intrusion and provision has to be made to assure lubrication of the bearings while operating at an incline. Some manufacturers offer heavier shafts and bearings for their ladderpumps in recognition of the fact these pumps have the potential to pump slurries with much higher densities than their hullpump brethren. I repeat; the same shell, liners and impeller are used in both pumps.

What then is the ladderpump’s mystique? It is that same mantra that applies to real estate — location, location, location.

Discharge-side limits

There should be no mystery about the ability of a ladderpump to pump to service the discharge pipeline. If the wetted parts are identical to those of a same-size hullpump, it follows that both pumps have the same capacity to move solids to discharge assuming that they are supplied with ample power and speed. If you rummage around in other papers in this collection you will learn that the length of discharge pipeline that can be served by a given pump depends largely on velocity and density. Slow the velocity, reduce the density, e—x—t—e—n—d the pipeline.

It is never our goal or intent to find ways to decrease density (production). To the contrary, we are always looking for ways to increase dredge production. There are many ways to do that including using a ladderpump. The point here is to bear in mind that if production in a given size pipe is increased by any means, the density has to increase which in turn may require a higher velocity and the net result will be a decrease in the maximum length of pipeline that can be served.

In assessing

the merits of ladderpump versus hullpump the above facts should at least serve as

footnotes to the claims of those who

tout, without qualification, the capability

of their ladderpumps to “double production.” Hell, it

may triple or quadruple production depending on what it was

before. The fact is that any pump not only has to take

in solids, it must deliver

them to discharge. Failure to make

provision for this fact will cause disappointment.

Suction side limits

Now we get to the nut of what makes ladderpumps so special:

LADDERPUMPS DO NOT HAVE SUCTION SIDE LIMITS

Wow, that is a large statement. It is, however, true.

A hullpump can develop a vacuum of about 25 inches of mercury at its suction inlet. Any attempt to increase that value will result in pump cavitation and a reduction in pumping action. Converting that 25 inches to productive potential depends on how high the pump is located above the water surface, the length of the suction pipe, the digging depth, velocity, density and several other factors. The operative factor is depth—as it increases, production must decrease.

When a hullpump is converted to a ladderpump the ability to develop vacuum does not increase! The ladderpump is still limited to about 25 inches of mercury, but by submerging it, the weight of the water above the pump becomes a big plus that can be added to the many other advantages that accrue to its location, location, location.

| We refer to pump suction inlet pressure in terms of vacuum because most dredge operators are familiar with that term. LADDERVAC, our electronic “vacuum” gauge system for ladderpumps, measures the differential pressure between the inside and outside of the suction pipe and is calibrated to readout inches of mercury. There is a direct mathematical relationship between inches of mercury vacuum and head (depth) of water. The pressure at the base of a 30-inch high column of mercury equals the pressure at the bottom of a 33-foot column of water. Using this relationship means that each foot of water depth equals 0.91 inches of mercury (30/33 = 0.909). |

Underwater, the 25 inches of vacuum that the pump can develop is increased by the weight of the water above it. If the pump is 20 feet below water surface, it will not cavitate until the suction inlet pressure reaches the equivalent of 43 inches of vacuum (25 inches plus 20 feet x 0.91 inches/foot = 43 inches).

A ladderpump also reaps the benefits of having a short, fairly straight suction pipe and operation with a shallow relative “digging depth”, attributes that are a plus for any dredge. A ladderpump, however, retains these benefits regardless of actual digging depth below the surface of the water. It is common for a ladderpump, even when producing high-density slurry, to develop a relatively low “vacuum”—equivalent to only 8 to 15 inches of mercury.

Other papers in this collection detail how the ability of a pump—particularly a hullpump—to take in solids relates directly to the pressure reduction (vacuum) that can be developed in the pump’s inlet and the consequent importance of conserving vacuum. Many papers in this collection are devoted to describing ways to conserve hullpump vacuum and thereby increase production.

A ladderpump does not suffer any suction-side limitation and therefore can take in solids at a rate far in excess of the pump’s ability to move those solids to discharge. If excess pumpable solids are available at the suction inlet, these pumps can take in slurry with a density of 50% by weight. Fifty percent by weight approximates the density found in a plugged discharge pipe, which makes impossible the goal of moving slurry with such a high density. Pumping slurry with forty to forty five percent density by weight is doable but seldom done. Achieving such performance requires sophisticated instruments and operating controls to maintain and regulate production. We offer these components, retrofit them in existing dredges and furnish them on our new dredges.

Other Considerations (the rest of the story)

Given the “limitless” productive capability of ladderpump dredges, one could conclude that every dredge should have a ladderpump. There is no shortage of pump and dredge purveyors who hold this view and they make recommendations for new equipment accordingly. A ladderpump dredge is not the answer to everyone’s prayers.

Many dredge peddlers recommend ladderpump a dredge because they do not know any better—they have never seen what a properly equipped hullpump dredge can do. They have not succeeded in making their hullpump machines perform anywhere near full capability so they cover their tails and hide their ignorance by recommending what they consider to be the sure-cure—a ladderpump.

Others, it seems, are driven by the profit motive. The high productive potential offered by a ladderpump dredge is accompanied by significantly higher acquisition cost which often translates into more profit for the dredge builder.

Potential customers come to us with requests for quotes on ladderpump dredges because others have assured them that a hullpump dredge cannot produce much of anything from depths greater than 35 feet.

Computer analysis is great tool for exploring the limits of the possible, however, it must be recognized that projected performance is usually difficult to replicate on a real dredge. It is difficult to avoid all the cackling that goes on about pumping high-density slurries. High production does ride through a discharge pipe as part of a high-density slurry, but folks, reality has to prevail. Pumping slurry with a density of forty percent by weight is no small accomplishment. It is hard to do. It cannot be done absent the right machine and the proper controls and instruments. Thirty percent slurries are much easier to achieve and somewhat more common.

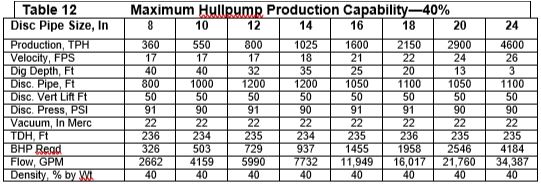

Let me use a little computer analysis to throw cold water on those who are so hot on the idea of pumping 40 percent solids by weight. See Table 12.

Table 12 shows the maximum digging depth and the productive capability of 8-inch through 24-inch hullpump dredges when pumping a coarse sand slurry containing 40 percent solids by weight. I venture to say that damn few dredge operators have ever achieved such high rates of production to say nothing of averaging them. Note that the small to medium sized sand and gravel hullpump dredges can raise 40% solids from a depth of 35 feet while the larger dredges have less depth capability.

We know of one 8-inch dredge that maintains an average production of 300 tph and a couple others that maintain a rate of about 275 tph. 360 tph is out of reach. How about a 12-inch dredge, hullpump or ladderpump, producing 800 tph? I have not seen a 12-inch dredge produce at that rate for long periods of time.

I submit that pumping 40 percent solids is not a practical goal for most dredges and those who blather on about such a feat should cool their jets.

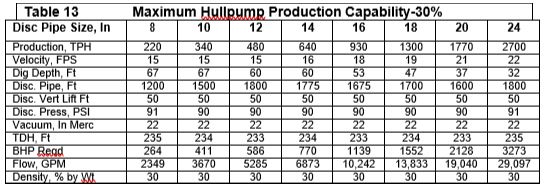

Let us examine hullpump performance with a more realistic goal—a more doable—30 percent solids. Take a look at Table 13.

The dredges shown in Table 13, with the exception of the 20-inch and 24-inch machines, are capable of producing at very good rates from depths of 50 feet or more.

As pointed out previously, computer projections may be difficult to replicate so discount the numbers by 25% to obtain a margin of safety and these dredges are still capable of producing at significant rates. Significant when you consider that some pump manufacturers tell their customers that hullpumps are only capable of pumping a maximum of 20% solids. These folks know not their products or the realities of practical dredge operation.

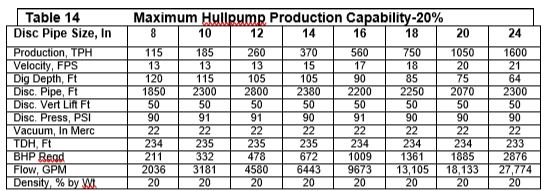

Table 14 is meant to dazzle the confused who cling to that clump of counterfactual, cock-and- bull claptrap which says that hullpumps are inherently limited to pumping 20% solids.

Note the depths from which these hullpump dredges can raise 20% solids. Reduce the depth to as shown in Tables 12 and 13 and density can increase. So much for the mythical 20% limit.

The point of these tables is to show what a hullpump dredge can do so a buyer can make an informed decision. I have no desire to talk a prospect out of buying a ladderpump dredge if that is what they want. A ladderpump dredge is never the wrong choice, but it may not be the best choice.

An example of this would be the new 12-inch ladder pump dredge with a forty-foot long ladder that I had the opportunity to visit. It was working in a location where the deposit was not and never will be over 25 feet deep—a clear case of overkill or overselling. This dumpy little thing featured hoist rigging that could not raise the cutter basket out of the water. The producer had to compensate for the manufacturer’s shabby engineering by keeping an excavator handy to lift the cutter clear of the water for maintenance.

Conclusion

The conclusion is that a potential dredge buyer has to do due diligence. Ask questions, visit working dredges, observe, ask more questions. Trust but verify. Do not limit your dredge research to a visit to a fabrication facility. There is no shortage of opinions and recommendations when it comes to dredge mining—much of it wrong. Willard Says papers offer valuable information—study them and if you don’t understand, ask.

Beware of the ladderpump “silver bullet” solution. Owners of underperforming hullpump dredges are often told to install a ladderpump and all of the production problems will be solved. This is good advice only if the hullpump dredge has all of the proper instruments and controls, the correct cutter, is pumping at the proper velocity and production is still limited because the dredge is continuously operating at the suction-side limit of the hullpump.

Visit operating dredges. Talk to the owners and operators. We can tell you that a 12-inch hullpump dredge can routinely produce an average of 450 tph from a depth of 60 feet. It is more meaningful if you see it for yourself and we can arrange for you to observe a dredge that has been doing that for several years.

We can tell you that a 10-inch hullpump dredge will routinely produce at the rate of 290 tph from a depth of 55 feet or you can watch it happen and decide for yourself.

If it is appropriate, we can put you on ladderpump dredges that are producing at higher rates or from much greater depths.

In all cases, you can talk to the folks that profit from the benefits of these machines.

A simple, serviceable and lower priced hullpump dredge will be suitable for most dredge mining applications from relatively shallow depths. What does “relatively shallow depth” mean? The tables above can provide some guidance about that.

Perhaps the next size larger hullpump dredge will produce at the desired rate.

If production demand dictates 30% slurry density from depths greater than 50 feet, by all means buy a ladderpump dredge.

Don’t buy horse pucky just to get the oats.

Comment, question, criticism, information on products mentioned? Contact willard@willardsays.com