Willard Says……

Use a velocity meter to maximize hydraulic dredge production and system efficiency. This instrument is the key to dredging success. Without a velocity meter, you cannot be serious in your pursuit of peak hydraulic dredge performance.

Velocity Facts:

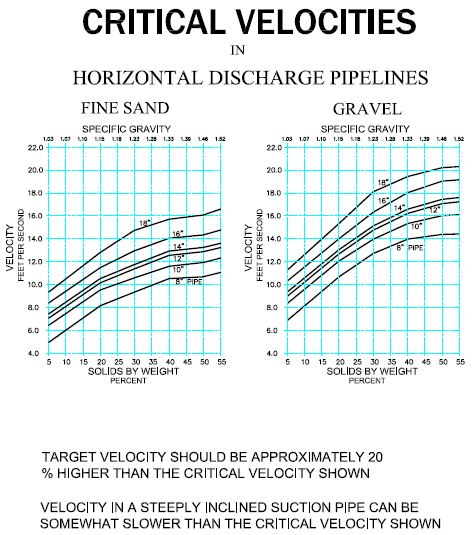

- Sand and gravel dredge operation is most efficient and productive when pipeline velocity is maintained at the target velocity, a rate that is about 20 percent faster than the critical velocity.

- Critical velocity is the flow rate at which solids start to fall out of the flow and form a bed on the bottom of the pipeline.

- Critical velocity varies with slurry density, solids particle size and pipe size.

- Critical velocity does not change whether the pipeline is 60, 600 or 6,000 feet in length as long as slurry density, solids particle size and pipe size remain the same.

- When pipeline length becomes so long that the pump(s) cannot maintain the target velocity the solution is to reduce production (density) or add a booster.

- The critical velocity for a particular set of dredge system conditions must be determined by experimenting and using the Theory of Elasticity.

- Velocity is the same at all points in the discharge pipeline as long as the inside diameter of the pipe is the same.

Operating Rules of Thumb:

A. Pipeline velocity varies with pump speed if density and particle size remains constant.

B. Pipeline velocity varies with slurry density if pump speed and particle size remain constant.

C. Solids production remains nearly constant if pump speed and velocity and particle size remain constant.

The Principle of Elasticity:

Elasticity or “elastic velocity” refers to a flow rate that increases promptly whenever pump speed is increased or density is decreased. We use this principal to find the critical velocity by incrementally reducing the operating velocity and repeatedly checking for elasticity. When a velocity is found to be inelastic (does not increase promptly) we have found the critical velocity so the target velocity can be determined.

As a general rule, the target velocity should be about 20 percent higher than the critical velocity. For instance a 10-fps critical velocity calls for a target velocity of 12 fps.

Note that a “prompt” increase in velocity will be considerable slower if the dredge is pumping through a very long pipeline as compared to a relatively short pipeline. The point is; velocity should start to increase as soon as the density is reduced or the pump speed increased.

Whenever there is a concern about pipeline plugging—always a worry—get to know and put Mr. Elasticity to work on the case.

Another way to determine if a bed of solids has formed on the bottom of the pipeline is to calculate the approximate time that it should take to clean out the pipeline after starting to pump clear water. Divide the length of the pipeline in feet by the velocity to get the number of seconds that it should take. For example, 1200 feet of pipeline flowing at 12 fps should clean out in about 1200/12 = 100 seconds or less than two minutes. If it takes longer to clear the pipeline the target velocity is too slow—there was a bed of solids on the bottom of the pipe.

Pipeline Flow Behavior

At critical velocity the flow rate is barely fast enough to keep the solids particles in suspension. If velocity slows to less than the critical velocity, some of the solids particles will fall out of the flow and come to rest on the bottom of the pipe. At first, the settling solids form a sliding bed. If you hear a pipeline making a periodic, sliding/scraping sound, you are hearing a sliding bed happening. If velocity slows even further, the sliding bed will stop and form a stationary bed. The stationary bed occupies a portion of the pipe’s cross- sectional area so the result is the same as if the pipeline were changed out to a smaller size.

This is a bad situation: the end of the road—a plugged pipe—can be seen from here. What was 12-inch discharge pipeline becomes an 11-inch pipeline: or worse, a 10-inch. Additional settled solids could easily cause the pipe size to go to zip unless something is done. We need to determine the critical velocity, operate at the target velocity and avoid this scenario.

We must maintain turbulent flow so that all the solids move at nearly the same rate as the water while keeping in mind that it is wasteful, inefficient and unproductive to maintain a velocity that is faster than the target velocity.

A word about efficiency. Do not confuse dredge system efficiency with dredge pump efficiency. Seldom will maximum dredge system efficiency flow rates match the flow and head conditions that will permit the dredge pump to operate at its maximum efficiency. The lower cost to operate a dredge system at maximum efficiency far outweighs the increased cost (if any) of failing to achieve maximum pump efficiency.

Recommended operating procedure:

We will use the above Velocity Facts, Rules of Thumb, Principle of Elasticity and the Critical Velocities chart below to describe how to maximize or regulate production while operating at best dredge system efficiency.

Refer to the Critical Velocity chart above. Assume we have a 12-inch ID pipeline with the goal of pumping gravel with a density of 25 percent by weight. On the “Gravel” chart find and go up the 25 Percent Solids by Weight line to its intersection with the line labeled 12”.

From that intersection, go horizontally to the left and find that the critical velocity is slightly less than 14 fps. The target velocity should be 14 (assumed critical velocity) plus 20% (14 x 0.2 = 2.8) = 16.8 or 17 fps.

We begin pumping by running the pump fast enough to achieve a velocity of 17 fps. As solids enter the dredge system, the velocity will decrease and we counteract by increasing the pump speed to keep the velocity at 17 fps. Slowly increase the vacuum and continue to increase the pump speed to maintain 17 fps. Continue this procedure until one of the following limits is found:

A. Pump speed cannot be increased.

B. Vacuum is just below cavitation point.

C. Plant is overloaded with solids.

D. Velocity falls below 17 fps.

A. Pump Speed Limitation

The pump cannot be run any faster, the plant is not overloaded and the velocity will fall below 17 fps if the vacuum is increased. The dredge is producing at its maximum under these conditions. It may have more productive capacity at a lower velocity and we can find that out by incrementally lowering the velocity by increasing the vacuum (density) and test for elasticity. Find the critical velocity; run at target velocity.

B. Vacuum Limitation

The vacuum cannot increase without cavitating, the pump could run faster, the plant is not at capacity and the velocity is 17 fps. This is a suction-side-limited dredge; producing at its maximum under these conditions. It may have more productive capacity at a lower velocity and we can find that out by maintaining maximum vacuum, lowering the velocity by incrementally decreasing pump speed and testing for elasticity. Find the critical velocity; run at target velocity.

C. Plant is Full

The vacuum can increase, the pump could run faster, the velocity is 17 fps and the plant is at capacity. The dredge is not producing at its maximum, but we need to determine whether it is operating at maximum efficiency. It may be more efficient if it can keep the plant full at a lower velocity. We can find the critical velocity by incrementally decreasing pump speed, adjusting vacuum as required to incrementally lower the velocity and testing frequently for elasticity. Find the critical velocity; run at target velocity.

D. Velocity Falls

The pump cannot run faster, the plant can accept more and the velocity will fall below 17 fps if the vacuum is increased. The dredge is producing at its maximum under these conditions. It may be more efficient and productive at a lower velocity. We can find that out by maintaining maximum pump speed, incrementally lowering the velocity by increasing vacuum and testing for elasticity. Find the critical velocity; run at target velocity.

Successful Operation

| The Goal To accomplish productive and efficient dredge operation by moving a high-density mixture through the discharge pipe at the target velocity without interruption. |

The most productive procedure for operating a sand and gravel dredge is to determine a target velocity, vary the vacuum as required to maintain the target velocity and set the pump speed at a rate that results in the desired rate of production.

Some deposits contain concentrations of same-size particles that cause the particle size distribution to vary widely in different areas and operators must be aware of significant changes in the nature of the slurry they are pumping. If the slurry contains an increased quantity of gravel or larger sized particles, the target velocity will have to increase to maintain a constant rate of production. Likewise, if the slurry particles decrease markedly in size, the pump speed may have to decrease to prevent the process plant from being overloaded with fine material.

Once determined, all operating personnel should maintain the target velocity and pump speed until conditions dictate a change. There is no reason for each operator to pump at a velocity or with a pump speed that is different from the settings that have been determined to be most productive and efficient. Operators should not be permitted to jump on a dredge and go riding off, each in his own direction.

Require operators to adjust vacuum upward to cause the velocity to slow when it rises above the target velocity and adjust vacuum downward when the velocity falls below the target velocity. The result will be a nearly constant rate of solids

Productive and efficient dredging; moving a high-density mixture through the discharge pipe at the target velocity without interruption cannot be done without a velocity meter.

The pump speed should be changed only to accommodate a change in production rate or to accommodate a significant change in slurry particle size. A temporary change in pump speed may be necessary to maintain velocity when a cave-in causes a high-density “slug” to enter the dredge system. Return to normal pump speed once the emergency is past.

Roadblocks in the Way of Success

- Success depends entirely on the ability of an attentive operator to readily adjust the vacuum.

- Success depends on the continuous presence of an ample supply of pumpable solids at the suction inlet.

- Success depends on an effective digging device to assure a continuous supply of pumpable solids at the suction inlet.

- Success requires that the dredge be fitted out to employ the digging device in an effective manner.

- Success is hard to achieve with a plain suction dredge. Eunuch class dredges don’t cut it.

- Success using high-horsepower arrays of inefficient water jets to loosen solids at the suction inlet is like using a sledgehammer to kill flies—a lot of energy is expended to achieve paltry results.

- Success is much easier to achieve with the aid of a CONVAC modulating bypass valve system. CONVAC eliminates interruptions, reduces the operator’s workload, reduces operator stress, and automatically maintains vacuum at the desired value while guarding against pipeline plugging.

The goal stated above cannot be realized if any of these roadblocks are present—eliminate them and you will be rewarded.

We have velocity meter kits in stock and send them out on a 30-day trial basis. It will take about an hour to install. All wiring and instructions are included. No cutting or welding required. Uses 12 or 24 VDC or 120 VAC.

How can you continue to miss out on unrealized production that can be yours using this marvelous instrument? You will never invest $3,000 and get it back any faster; some have paid for it out of increased production before the 30 days was up. After that you get to enjoy all the higher profits.

Comment, question, criticism, information on products mentioned? Contact