Willard Says……

The Discharge Pipeline—How Far Can a Pump Pump?

Sorry to say there is no simple answer. A valid analysis made with the goal of forecasting how far a dredge pump can pump must take into account the following variables:

Design variables:

-

- Pump efficiency.

- Available horsepower.

- Available pump speed

- Pipeline diameter.

- Static lift.

- Dredge Suitability.

Operating variables:

-

- Slurry density (Rate of production).

- Feed rate regulation.

- Velocity.

- Solids particle size & distribution.

- Availability of pumpable solids.

All of these factors influence a dredge pump’s maximum pipeline “range”. Some of them are design variables and others are operating variables. Design variables are those that were made constants by the choices made when specifying the dredge/pipeline/process plant.

Operating variables such as density, feed rate and velocity can be converted to constants by the effective use of instruments and controls.

Uncontrollable factors—availability of pumpable solids and particle size and distribution—are unique to each deposit and may vary widely. Hopefully, the dredge is equipped to deal with these factors and maintain a satisfactory rate of production. If not, a more effective digging device may need to be employed.

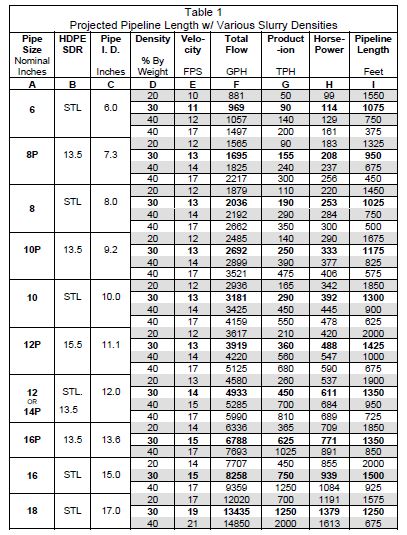

Table 1 shows the

length of pipeline that can be expected for various sizes of pipe under various

operating conditions.

Column Key

Other factors

Static Lift. Assumed to be 40 feet for all calculations. A greater lift will decrease the length of pipe and a lower lift will enable an increase in pipe length.

Relationships

The first and most important relationship is the one between the rate of production and the requirement that production be continuous. The production rates/pipeline lengths shown in Table 1 are possible only when the rate is continuous without “gaps” or “slugs”. Most dredge operators can average the poor rate of twenty-percent solids by weight. A competent operator can achieve a thirty-percent average in a “good” deposit.

Difficulties arise when the average slurry density approaches forty-percent solids by weight. Such high densities require sophisticated controls and instruments such as Twinkle Co’s CONVAC suction side stability system. The automation provided by this controller assures a continuous, regulated flow of solids into the dredge system and prevents chokeoff due to cave-ins.

Another important relationship is the effect that velocity has on pipeline length, production and horsepower. Target velocity is that velocity that is just faster than the critical velocity, which is the velocity at which solids commence to fall out of the flow and come to rest on the bottom of the pipe. Strive to determine and maintain flow at the target velocity.

It is assumed that the dredge system is adequate to the task of supplying sufficient solids and flows to obtain the listed rates of production and flow. Total flow depends upon the pipe inside diameter and the velocity. The flows are listed to provide guidance in selection of process plant components.

ANALYSIS

The values listed in Table 1 were generated using a dredge production spreadsheet that has been refined through years of observing the performance of many dredge systems.

These theoretical projections provide some insight as to how a dredge system can be expected to perform under ideal conditions and to see how a change in one variable can affect dredge performance. As such, the projected results shown do not constitute a warranty of performance of any kind.

Contact willard@willardsays.com for more information, comment or criticism.